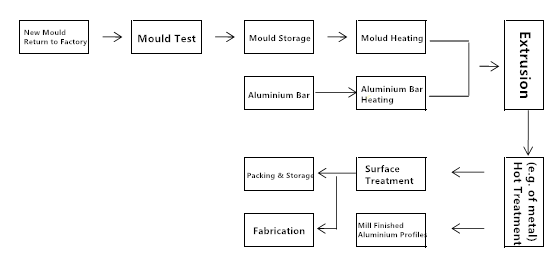

We have models with different specifications of 630 tons, 1100 tons, and 1500 tons, all equipped with fully automatic dual traction machines and efficient quenching systems. With the aim of meeting customer needs, we strive for progress and continuous innovation, achieving an annual production of 12000 tons of aluminum materials.

Production workflow system: extrusion production line, oxidation and coloring production line, spraying production line, deep processing production line, door and window finished product processing center

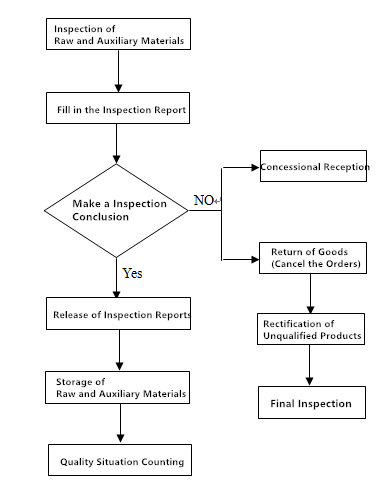

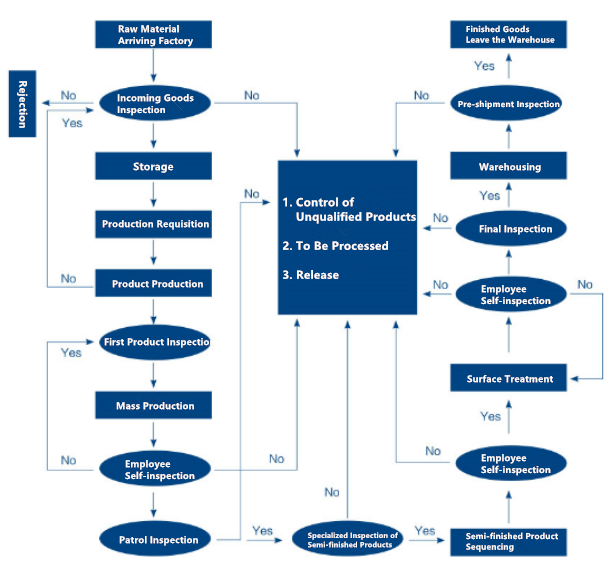

Quality control process system: Sailu advocates a people-oriented and customer-oriented corporate spirit. Establish a "Technical Quality Department" specifically responsible for product quality inspection, and implement a "secondary inspection" combining "self inspection" and "special inspection" in the control process of process and product quality, to ensure that "unqualified products do not leave the factory". Adhere to the "supervision of the next process and the combination of process self inspection and quality inspection monitoring" of the entire staff quality monitoring system, ensuring product quality and long-term stability.

Process inspection: The reasonable setting of process control and quality control points is a key factor in ensuring product quality. According to the actual situation, quality inspection control points have been set up in raw material storage, profile extrusion molding, surface treatment, finished product warehousing, product delivery, and various process transitions. Combined with self inspection of each production process, it ensures that the product is fully controlled throughout the entire process.